M'mafakitale ena opangira zitsulo zolemera, monga mafakitale opangira zombo, makina opangira migodi, ndi makina omanga, nthawi zambiri amakumana ndi mavuto ngati awa: momwe mungakwaniritsire kuwotcherera kolimba kwa magawo azitsulo ndi zitsulo?Kawirikawiri, mbali zachitsulo zidzawonetsa malo odulidwa pambuyo pa ndondomeko yowonongeka.Pofuna kuti mawonekedwe a mbali zowotcherera azitha kuphatikizika, ndikofunikira kukonza ma bevel amitundu yosiyanasiyana yamitundu yosiyanasiyana m'mphepete mwa zidutswa ziwiri zachitsulo, kenako kuchita kuwotcherera kumaso.Posachedwa, Knoppo yakhazikitsa KP Series (mphamvu kuchokera ku 30000W mpaka 8000W) Mapepala.CHIKWANGWANI laser bevel kudula makina, yomwe idzathetsere mavuto oterowo, kuchepetsa njira zovuta, ndikupulumutsa kwambiri nthawi ndi mtengo.

M'mbuyomufiber laser kudulaukadaulo, ukadaulo wodula bevel udagwiritsidwanso ntchito munjira zopangira zitsulo monga lawi lamoto ndi kudula kwa plasma.Komabe, njira yachikhalidwe yodulira lawi lamoto idzatulutsa mabala akuya, ndipo panjira zovuta za groove, luso ndi ntchito ya ogwira ntchito ziyenera kukhala akatswiri kwambiri, ndipo kusasinthika kwa kuwotcherera sikungakhutitsidwe bwino;kudula kwa plasma Ponseponse, zomwe zimapangitsa kuti zikhale zolondola kwambiri, komanso zoopsa monga ma radiation a arc, utsi ndi phokoso zidzapangidwa panthawi yodula.

Mitundu iwiri yomwe ili pamwambapa ya njira zodulira ndi ya njira yayikulu yopangira gwero la kutentha.Mbaleyo idzapunduka mwa thermally pansi pa njira yopangira matenthedwe, ndipo njira yowonongeka iyenera kukonzedwa pambuyo pomaliza.Poyerekeza ndi njira yachikhalidwe yopangira beveling, laser ndi njira yatsopano yosinthira yokhala ndi mapindikidwe ang'onoang'ono amafuta, mawonekedwe abwino kwambiri, kulondola kwapamwamba kwambiri komanso kukhazikika kwabwino pamsika.

Knoppo KP mndandandapepala CHIKWANGWANI laser beveling kudula makinaakhoza kwambiri kusintha kuwotcherera kulimba, kuwotcherera maphatikizidwe ndi workpiece aesthetics ndi pokonza poyambira ena mawonekedwe a geometric mu kukhala-welded mbali ya weldment.Kwa chitsulo cha alloy, poyambira imathanso kutenga gawo pakusintha chiŵerengero chazitsulo zoyambira ndi zitsulo zodzaza.

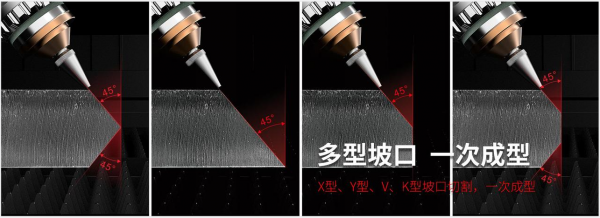

Malinga ndi makulidwe osiyanasiyana ndi mawonekedwe akuthupi a mbale zosiyanasiyana, kusankha kwa mitundu ya beveling ndikosiyananso.Mitundu yowoneka bwino pamsika imaphatikizapo groove yooneka ngati X, groove yooneka ngati V, yoboola ngati Y, yoboola pakati pa K, ndi zina zotere. post-kuwotcherera ndondomeko.Kuchuluka kwa kuwotcherera kukukulirakulira, poyambira ngati K kapena poyambira X nthawi zambiri amagwiritsidwa ntchito.Pa makulidwe omwewo, kuchuluka kwa chitsulo chowotcherera kumatha kuchepetsedwa pafupifupi 1/2, ndipo kuwotcherera kumakhala kofanana, ndipo kupindika pambuyo pakuwotcherera kumakhala kochepa.

Kodi makina odulira a knoppo fiber laser beveling ndi chiyani?

Choyamba, poyambira wa mawonekedwe ena amtundu wa geometric amatha kukonzedwa mwachindunji pagawo loti-welded wa weldment, kuti kuwotcherera msoko ndikulowa kwathunthu kwa makulidwe awotcherera atha kupezeka munjira yowotcherera, kuti atsimikizire. mphamvu kuwotcherera wa weldment ndi kuchepetsa njira zosafunika., kukwaniritsa zotsatira zochulukitsa;

Chachiwiri, poyerekeza ndi moto wamba ndi plasma bevel processing, laser processing ndi bwino kwambiri ndipo amapulumutsa zipangizo.Mwachitsanzo, m'makampani opanga zombo, kugwiritsa ntchito ukadaulo wa laser bevel kudula pokonza zigawo zooneka ngati T zachitsulo chochepa cha aloyi zimatha kupulumutsa kwambiri zida zazitsulo za aloyi ndikuwonetsetsa kuti sitimayo ikhazikika;

Chachitatu, laser processing ali ndi ubwino pang'ono mapindikidwe matenthedwe, khola kudula khalidwe ndi mkulu mwatsatanetsatane.Kulumikizana bwino.

Pakali pano, Knoppo laser bevel kudula luso lakwaniritsa Kuphunzira zonse mu pepala zitsulo processing ndi processing mbiri, ndi luso ali osiyanasiyana ntchito, kuphimba shipbuilding, mafakitale refrigeration, makina zomangamanga, makina migodi, mapaipi mafuta, etc.

Nthawi yotumiza: Jul-08-2022